Toggle bolt and driver

Product Development Case Study

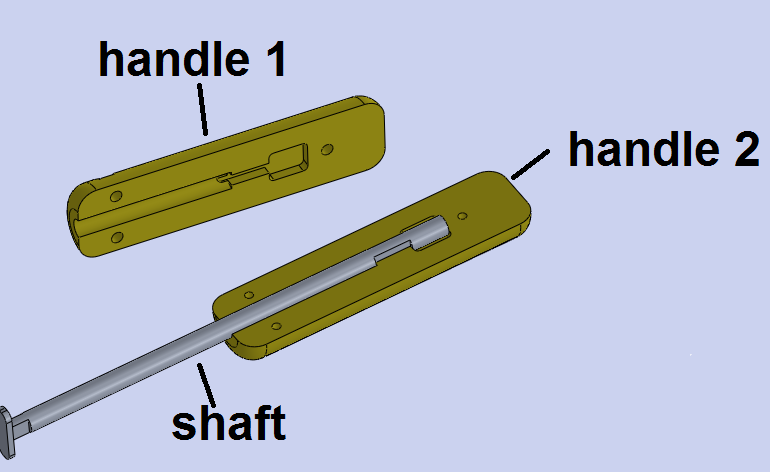

In this Remco product development case study, a customer came to us with a unique product concept – a toggle bolt and driver set that would connect the driver and bolt, making it easier to install the toggle bolt into the wall.

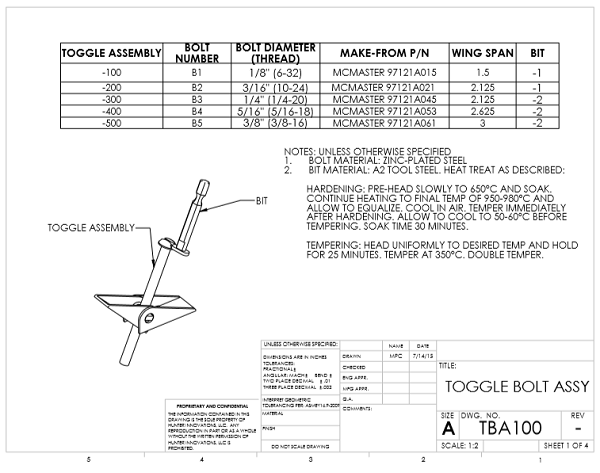

Remco engineers took this concept and developed a unique new toggle bolt and driver product ready for mass market release. We helped the customer obtain a patent, delivered a complete set of engineering documentation (3D models and drawings), and helped the customer source the product for production, at which point the product was handed off to the customer.

Preliminary Design

We took the customer’s input and created several iterations of the design that were ready for customer feedback and, in some cases, prototyping and testing. Deliverables from this phase typically include a set of detailed design requirements, a high-level design, 3D models ready for prototyping, and customer approval of the high-level design. For most customers, this phase culminates in a PDR, or Preliminary Design Review.

Detail design

In the detail design phase, prototypes and test samples are fabricated and tested, and a final design is selected and finished. Typically, the detail design phase ends with a CDR, or Critical Design Review, where the customer has the opportunity to review the final design models and drawings, test results, and final product specifications.

Production Launch

In this phase, we decide whether to make or buy the product, identify and down-select suppliers, get samples and first-articles made, finalize supplier and customer contracts, and begin producing the product. In this case, the program was handed over to the customer once supplier selection was complete.