Remco Case Studies

Browse examples of a few of our previous projects.

Manufacturing: Rotor disk Machining Process

This manufacturing case study involved the creation of some unique tooling to locate and some testing on a wire EDM to machine a turbine rotor disk. The customer, a manufacturer of turbine engine disks, was interested in replacing their traditional horizontal broaching process. Remco engineers ran trials on a wire EDM, designed and built fixturing, and handed a production-ready process to the customer to improve their up-time, tooling costs, and yield.

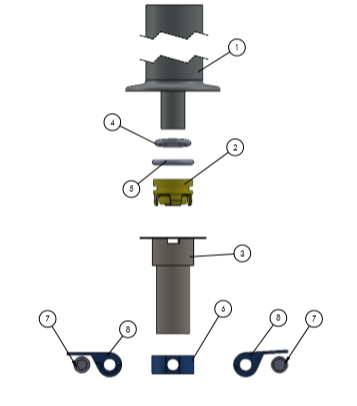

Product Development: Toggle bolt & driver

This product development project was undertaken at the request of a commercial business customer with the idea to bring a new product to market. Remco took the product through the development cycle, starting with preliminary engineering, testing and validating the product, procuring prototypes, obtaining a patent so the customer could bring the target into mass production.

Product Development: Faucet Install Fixture

This project was done for another commercial customer with a product concept. Remco engineers developed this unique quick-installation fixture for standard kitchen sink faucets and delivered the design to the customer, assisted in obtaining patents, and developed suppliers for the product.

Engineering: Custom Die Cutter Press

A medical device company needed help improving throughput in one of their manufacturing cells. The Remco team developed a fully custom, semi-automated die cutting press that replaced a tedious and dangerous hand-cutting operation, removed a production bottleneck and resulted in much smoother and more predictable output for the cell.

Product Development: Ortho Ankle Brace

Remco helped develop an orthopedic ankle brace for a non-profit company with a production facility in Haiti to support economic growth in an underdeveloped community.