Rotor Disk Process Improvement

Manufacturing Case Study

This project was completed for an industrial turbine engine manufacturer that was interested in replacing their traditional horizontal broaching process, which had been used for years to machine fir trees into their rotor disks. Remco was engaged to explore the feasibility of replacing the old process with a wire EDM machine, which would reduce tooling costs and potentially eliminate some quality issues.

Remco conducted the feasibility study by running trials with a wire EDM machine, developing a process and tooling for the new machine, and turning over the process to the customer. The result was a comparable process time, improved yield, and reduced tooling costs in the long run.

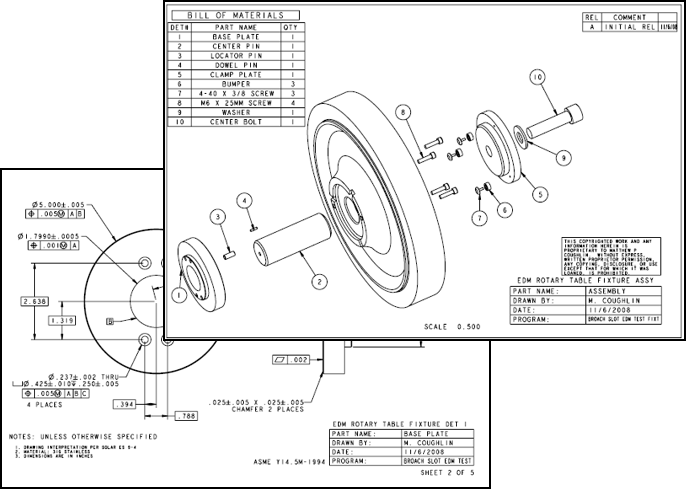

Remco engineers also designed unique tooling and fixtures, required to support and locate the disks at a compound angle and hold the tight tolerances required for the machined features.